OUR JOURNEY CONTINUES

We calculated our CO₂ footprint for the first time in 2021 and offset our emissions through climate protection projects.

Together with the Cologne-based start-up Planted, we have continued this path. Planted helped us to execute a complete CO₂ accounting for the fiscal year 2022 and determine our carbon footprint.

HERE'S HOW WE DID IT

To determine our CO₂ footprint, we considered all activities and processes associated with our work. We focused on all emissions caused along the entire value chain on which we, as a manufacturing company, have a direct influence.

Emissions within a CO₂ balance are divided into different areas, known as scopes. Scope 1 includes all direct emissions from combustion processes, Scope 2 encompasses indirect emissions, e.g., from purchased electricity, and Scope 3 considers all indirect emissions related to the company's activities in the upstream and downstream value chain.

For us, the relevant categories in Scope 1, 2, and 3 were calculated.

The relevance of the categories to be considered is determined both by the available data and the relevance of a company's activities.

Direct emissions (Scope 1), for example, include the company's own fleet. Since they are caused within the company, Scope 1 emissions can be relatively easily measured and controlled.

Indirect emissions include purchased energies such as electricity or heat (Scope 2). In Scope 3, the focus was on collecting data for our Cologne office and our team. This includes, for example, business trips and the team's commuting. In addition, all production-related emissions were calculated in Scope 3. This includes material procurement, production, and transportation to our manufacturers, as well as further transport to our warehouse and to our customers.

THIS IS HOW BIG OUR FOOTPRINT REALLY IS

To the result of the calculation: In total, we are responsible for the emission of 874.83 tons of CO₂ in 2022.

Being responsible and bearing responsibility for something has two sides for us: Manufacturing new products inevitably entails the generating of emissions. We are aware of this and want to take responsibility within our capabilities.

As a company, we want to act as sustainably as possible and harm the environment as little as possible. Our short-term and immediately implementable approach, therefore, remains in place: We record our emissions and offset them.

In addition, we keep our long-term goal of making production and the entire value chain less emission-intensive firmly in sight.

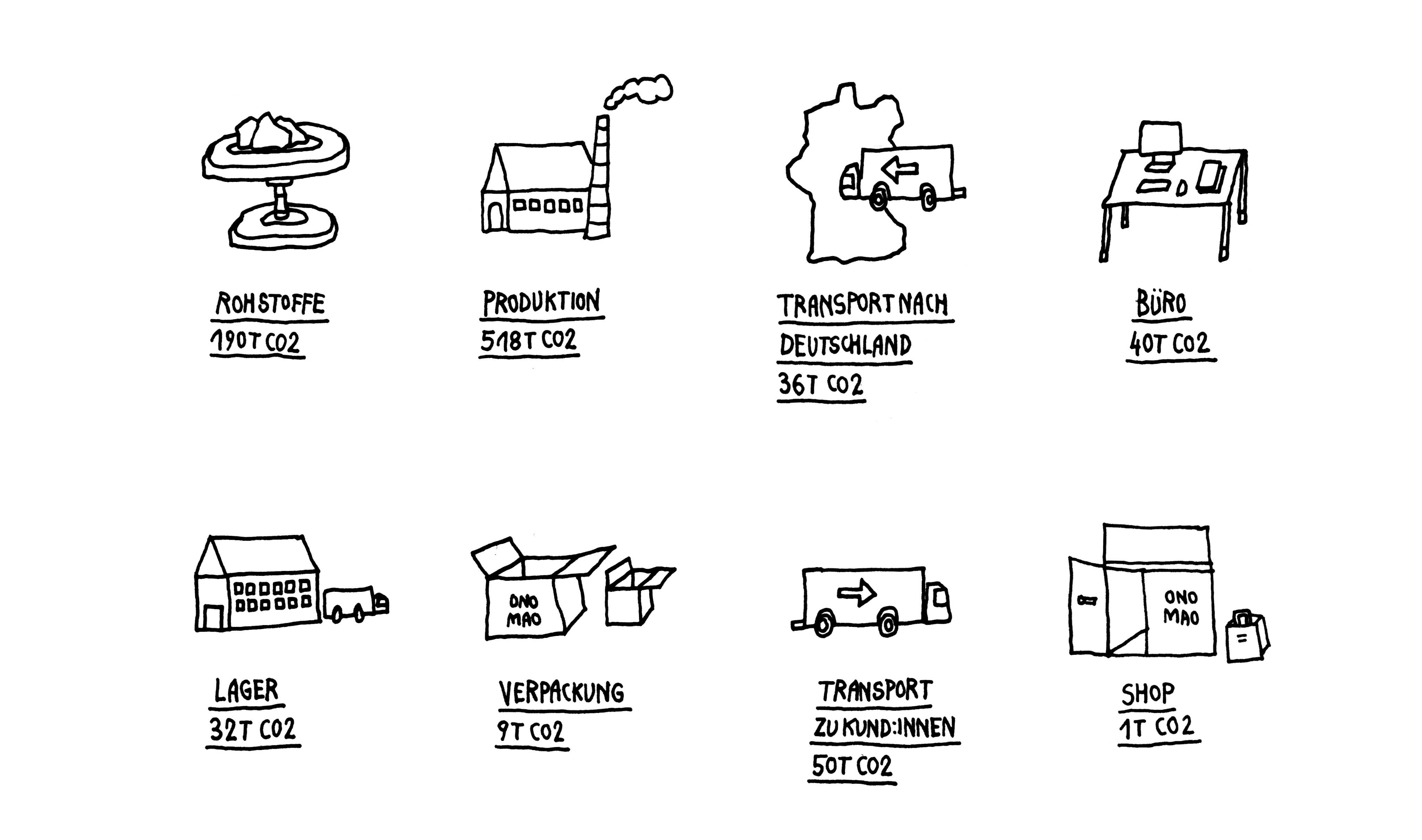

THE EMISSIONS WE CAUSED ARE DISTRIBUTED AS FOLLOWS:

73.32%, or 641.4 tons of CO₂e*, come from so-called other indirect emissions from Scope 3. As a manufacturing company, purchased goods at 58.62% and heat at 23.81% are the primary sources of these emissions.

25.13%, or 219.81 tons of CO₂e, are direct emissions from Scope 1, only 1.56%, or 13.62 tons of CO₂e, result from indirect emissions through grid-bound energies (Scope 2).

To better understand and illustrate our overall footprint, we have divided all values into eight categories that reflect our activities along the entire value chain, starting from raw materials through production and transport to our customers:

*CO₂ equivalents (CO₂e) are a unit of measurement for standardizing the climate impact of different greenhouse gases.

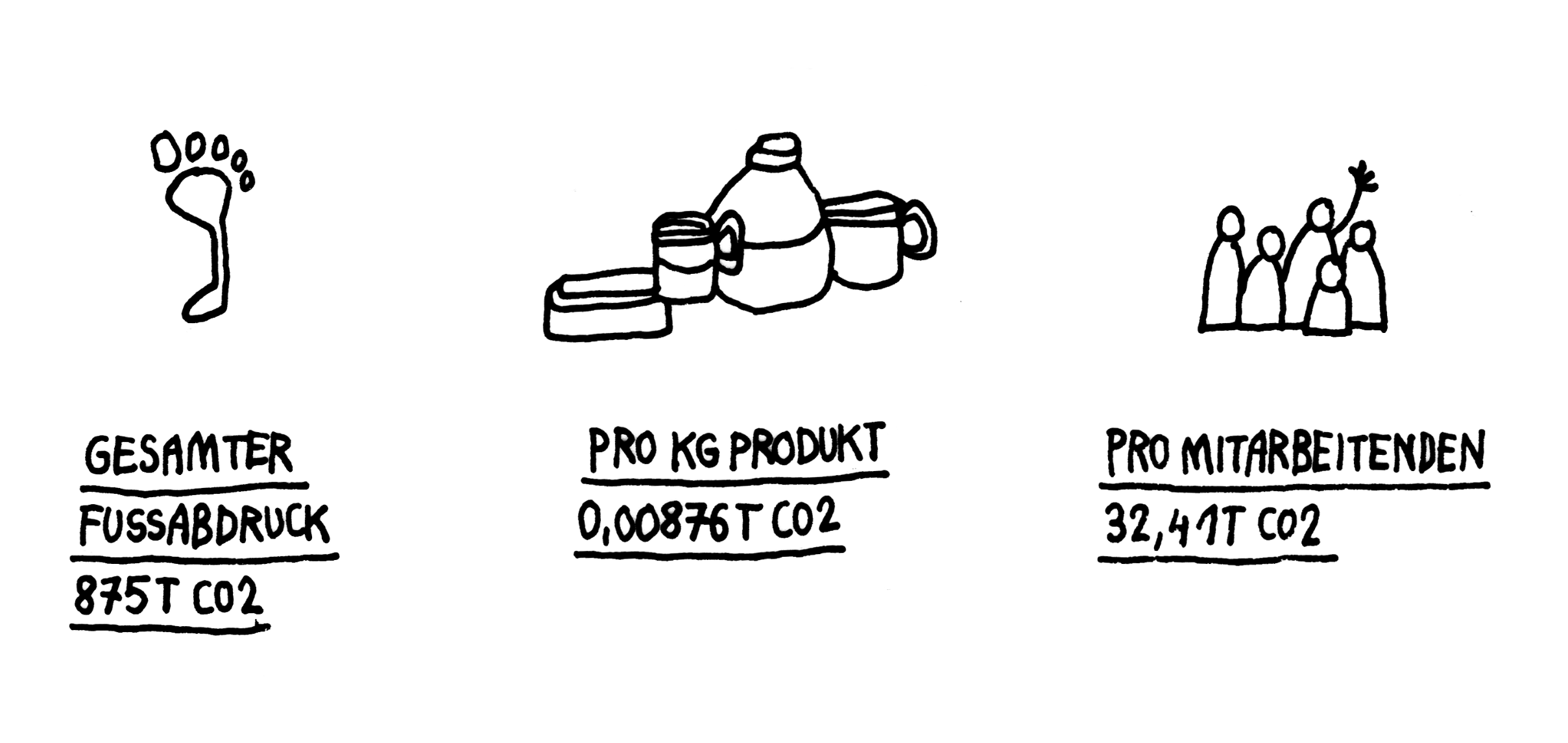

ILLUSTRATION OF OUR CARBON FOOTPRINT

To better visualize our CO₂ footprint, we asked Planted to relate it to our pillars - the products and our team - and calculate the emissions per kilogram of product and per employee.

For about 176,600 products, which together weigh just under a ton, the production of one kilogram of product causes about 0.00876 tons of CO₂e.

For 12.65 employees (based on a regular 40-hour week), each team member has emitted an average of about 32.41 tons of CO₂ in the course of their work for onomao. In reality, it is much less, as our team is larger, but most do not work a classic 40 hours per week.

OUR THOUGHTS ON THE CALCULATION AND OUR RESULT

We want to be transparent and honest: Compared to the previous year, according to the calculations by Climate Partner in 2021 and Planted in 2022, we have caused about 100 tons less CO₂ emissions.

However, since we have not been able to make any relevant adjustments for a decrease in emissions in the meantime, we took a close look at and compared the calculation bases of the two years: In 2021, the Product Carbon Footprint, i.e., the footprint of each product, was included in the calculation. The Product Carbon Footprint not only calculates the lifecycle of the products but also considers the end-of-life emissions that occur when products are disposed of. This accounted for almost 83 tons in the overall balance.

OUR PRODUCTS ARE ROBUST AND TIMELESS, THUS NOT DESIGNED FOR QUICK DISPOSAL

Against this background, Planted focused the current calculation solely on the Corporate Carbon Footprint, which considers the manufacturing phase of our products and excludes disposal.

Moreover, Climate Partner calculates a 10% safety margin. This added another 94.87 tons to the calculation, which was omitted in Planted's calculation.

Another difference that became apparent in the final result of both calculations is the total amount of goods purchased. In 2022, compared to the previous year, we bought approximately 100 tons less in raw materials.

Despite certain differences, such as varying emission factors, the calculations from both years are essentially based on similar foundations and databases.

WHAT ASPECTS CAN BE IMPROVED AND ARE TO BE ENHANCED IN THE COMING YEAR?

Currently, we are following the path in sustainability and climate protection that we can pursue within our capabilities and that feels right for us. Despite all the positive aspects associated with this path, there are existing and constantly new hurdles and stumbling blocks that we must face and want to remove in the long term.

A first small obstacle we encounter is the data situation from the manufacturers in Portugal*, which should be more detailed. So far, our own data could compensate for the partially incomplete data from Portugal, so that the overall emissions would not have changed significantly. However, we are working on getting better data from our production sites for the coming calculation. Recently, we have received reinforcement in the team for production and supply chain management.

*Unfortunately, our glass producer in Spain was unable to provide us with data, so in this case, we could only rely on our own data and information on production, order volume, and delivery routes.

THE CO₂ BALANCE REMAINS A PRIMARY LEVER FOR US

Once we have listed and understood all activities that cause emissions, we can then develop reduction possibilities and implement measures for reduction.

Our goal from the previous year remains: We aim to reduce our ecological footprint and become overall more energy-efficient and greener.

Here you can learn more about the CO₂ offsetting of our Cologne location: sustainable energy systems for Vietnam.

And here you can learn more about the CO₂ offsetting of our production: efficient and clean cooking solutions for Ghana.