OUR PATH TO CLIMATE NEUTRALITY

Together with Climate Partner, we began in 2021 to work on the collection and evaluation of our emission values and to discuss options for compensation and solutions for permanent CO₂ reduction.

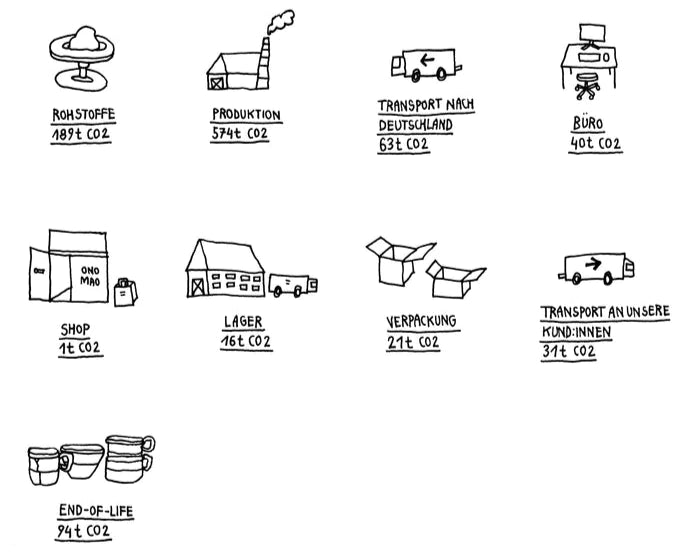

First, we recorded all the emissions we caused along the entire value chain last year: From raw materials to production and transport to use and finally, disposal of our products. Then, in order to be able to take a holistic view of emissions, we obtained information on our production sites in Portugal, on all transport and delivery routes, and on our Cologne site, consisting of the office, warehouse and our small store on Venloer Straße.

Our long-term goal is not only to determine the emissions and offset them through a climate protection project. We want to reduce the ecological footprint permanently we leave behind.

WE HAVE RECORDED ALL EMISSIONS FROM THE COLOGNE SITE AS WELL AS OUR PRODUCTION

To do this, we looked closely at how many emissions we consumed in their entirety in 2021. All the emissions of the Cologne site were combined under the so-called "Corporate Carbon Footprint". The Product Carbon Footprint looks at the entire life cycle of our products - from the extraction of raw materials to disposal.

Emissions at the Cologne site include the consumption of electricity and heat, our vehicle fleet, which consists of a van, the daily dose of coffee, business trips to our manufacturers, and our team's commute to work. All of this provides information on how large the CO₂ footprint is that we have left here in Cologne.

Based on the "product carbon footprint," the impact of a product along the entire value chain on our climate was also determined.

In order to be able to determine all the information, we got to the bottom of the following questions: Where do the raw materials of our carpets and ceramics come from? How much energy do our manufacturers use? What distances do our products travel? How are the products disposed of or recycled?

OUR EMISSIONS IN 2021

We were very excited to receive the results from Climate Partner after an enlightening if sometimes arduous, journey: We emitted a total of 1,043.57 metric tons of CO₂ across our entire operation in 2021.

We have therefore taken a look at our entire supply chain and selected and illustrated the most concise factors.

For us, this figure is and remains very abstract, even if we have a vague idea of how many carpets and cups have passed over the counter.

We have tried to get a little closer to this figure and to classify and illustrate the total CO₂ we have emitted.

Compared to the entire onomao venture in 2021, for example, we could have traveled 3,021,757 km by car, or about 1,500 times from Cologne to Portugal to visit our producers. That's quite a lot, and considering the many hours we would have to spend in the car, it's unimaginable.

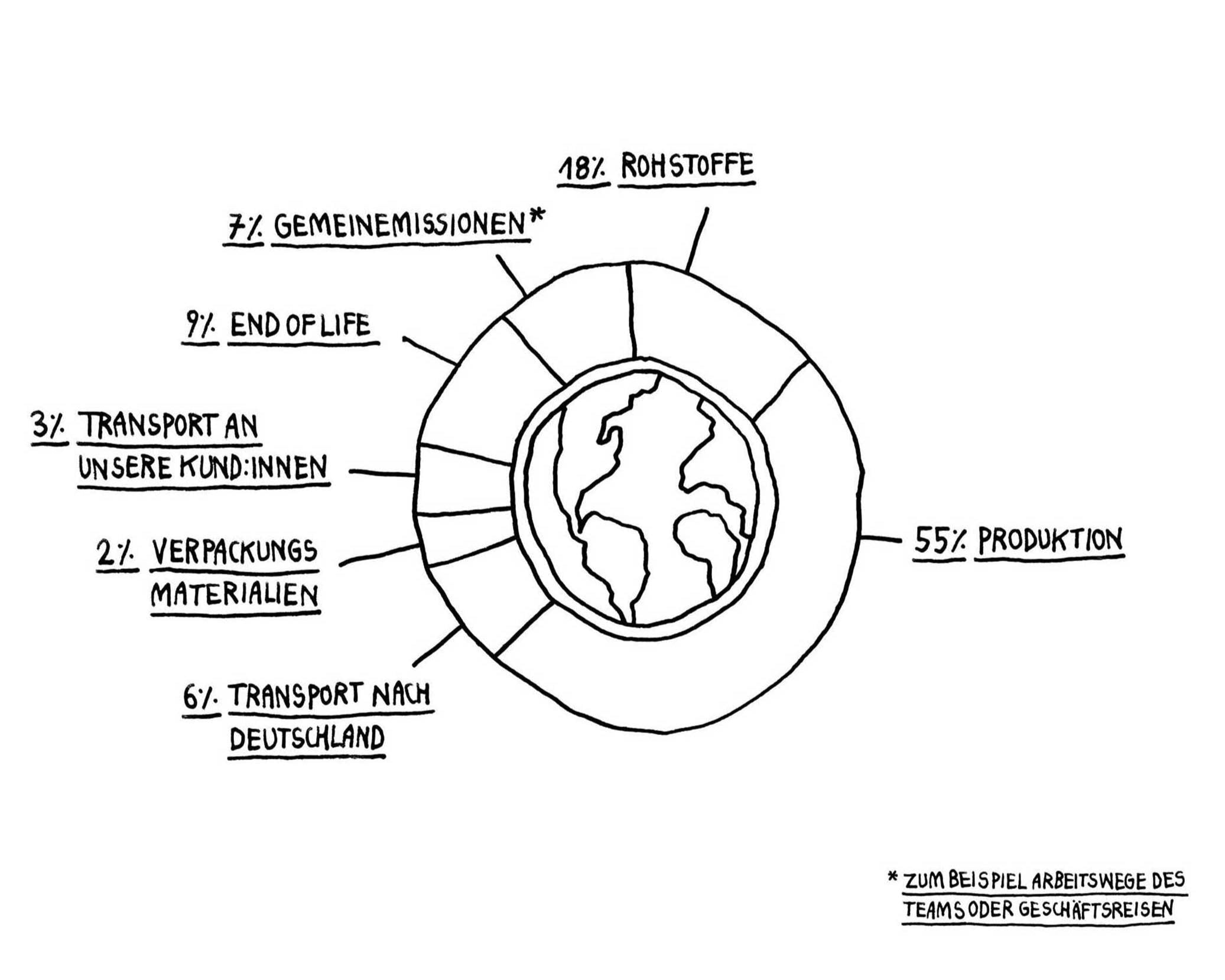

THE CO₂ FOOTPRINT OF OUR PRODUCT

73% of the emissions generated within our "Product Carbon Footprint" are associated with the manufacture of our products. As we are a manufacturing company, this result is understandable. We are aware that every moment we create products, we consume resources and, in the process, expend energy to manufacture our products. Overall, production accounts for 55% of total emissions, our raw materials account for 18% in comparison, and the so-called "end of life" factor, i.e., the disposal of our products, is listed at 9% in the overall balance.

THIS IS WHAT OUR NEXT STEPS LOOK LIKE

We have taken a close look at the results and considered where we can change procedures or processes in the short and long term in order to reduce our ecological footprint step by step and where the biggest lever is that we can use to make targeted changes.

Next, together with our producers, we would like to make production more energy-efficient and greener overall.

Since it will only be possible to reduce energy consumption in production in the long term, we first want to switch our entire production to green electricity. This will already reduce emissions by 28%.

In addition, we are already in concrete talks with one of our producers about the installation of solar cells. The switch to renewable energies is feasible in the short term and helps us to start at an essential point within our production process in order to no longer have to consume emission-intensive energies.

Nevertheless, we are pleased and proud to note that there are already many smaller and larger things that we are doing right to protect our environment. It is nice to see that even small adjustments can have a positive effect: A considerable part of our team comes to the office on foot or by bike, we use green electricity in our store as well as in the office, we use natural materials for our ceramics and by producing in Europe our products don't have to travel long distances. All this has a positive and direct impact on our ecological footprint.

WE COMPENSATE 100% OF OUR EMISSIONS!

In figures, this means we offset a total of 1,043.57 tons of CO₂ via climate protection projects.

We mean it when we write that we offset 100% of our emissions. This does not just mean the emissions that we have consumed here at our Cologne site, but all the emissions that we, as the saying goes, have to take responsibility for. This includes, among other things, the emissions of our producers and the entire logistics as well as the CO₂ emissions that would have to be spent to dispose of our products.

A SUMMARY

On our way to climate neutrality, we didn't have a clear idea at the beginning of how high our emissions were and where we could specifically reduce our emissions. The detailed recording of our data has helped us to get a more precise overview of the CO₂ emissions of all our processes.

We are aware that offsetting CO₂ is not the only right solution and is not sufficient to adequately protect the climate. But it is one of many possible approaches.

And even though emissions trading and CO₂ allowances can be viewed ambivalently, we have come to the conclusion that it is better to pay for offsets than not to do so.

We cannot reverse emissions and will continue to produce emissions in the future. Nevertheless, in order to take responsibility for our climate and our environment, our goal is not only to compensate for the emissions but to reduce them and thus become even more sustainable from now on.